With over 30 years of experience in bulk solids handling, Turbovent’s engineering team combines deep process expertise with advanced digital tools to deliver robust, efficient, and cost-effective solutions. We use state-of-the-art Siemens software for CAD, CAM, FEA, and CFD applications, enabling accurate design, simulation, and optimisation.

Our capabilities include:

1. CFD & Particle Studies

Analyse flow, pressure, and temperature in cyclones, calciners, bag houses, ESPs, and air pre-heater lines.

2. Flow Optimisation

CFD analysis of ducts and tube structures to improve distribution and reduce turbulence.

3. Equipment Efficiency

CFD-led optimisation to improve conveying system performance.

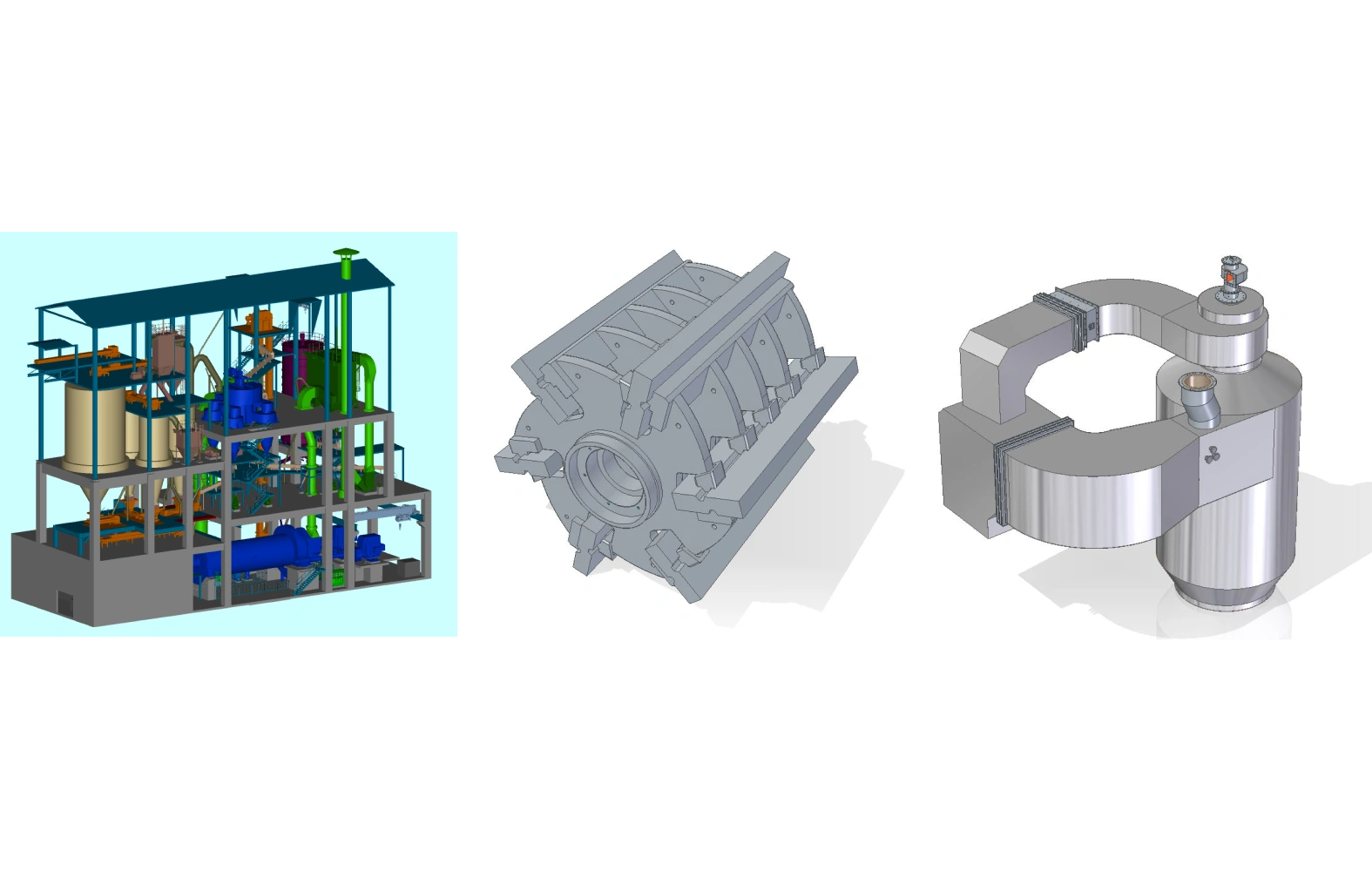

Detailed Engineering for Cement Production Units & Grinding Units

We provide comprehensive engineering and consulting services for cement plants up to 5,000 TPD and beyond, and grinding units up to 2 MTPA, utilizing Ball Mill, VRM, or Combi Circuit technologies — covering the full project lifecycle.

- Concept development and process design

- Detailed engineering and layout optimisation

- Equipment design and specifications

- Project management including procurement support, vendor coordination, erection supervision, and commissioning

By combining technical know-how with project management excellence, we enable clients to achieve efficient, reliable, and globally benchmarked facilities.

Plant Upgradation for Clinkerization units & Grinding Units

For cement units aiming to boost capacity, Turbovent delivers comprehensive expansion studies that balance technical feasibility with economic optimisation. Our studies include:

- Process analysis and capacity assessment

- Identification of expansion options

- Cost and profitability projections

- Technical recommendations and detailed design

- Layout modifications and implementation sequencing

These studies allow us to create actionable roadmaps that ensure capacity enhancements are efficient, profitable, and sustainable.

Energy Audit & Modernisation

With rising power costs, industries are under pressure to optimise energy use and adopt alternative fuels. Turbovent helps clients achieve this through:

- Assessment of current energy use

- Identification of energy-saving measures

- Evaluation of alternative fuel options

- Modernisation and retrofit planning

These services help industries reduce costs, improve efficiency, and transition to more sustainable operations.